\ Sûrement le meilleur choix de machines d’électroérosion au monde

L’expérience d’ONA est le meilleur choix qui s’offre à vous : l’équipe de personnes dotées de la plus grande expertise en matière d’usinage par électroérosion, ainsi qu’une approche technologique visant à offrir des solutions techniques personnalisées avec pour objectif de toujours répondre aux besoins particuliers de chaque client et d’assurer ainsi leur rentabilité future.

Et tout cela est fourni avec la garantie de qualité et de fiabilité offerte par une marque pionnière en matière d’usinage par électroérosion qui possède plus de 60 ans d’expérience dans le développement de solutions techniques adaptées aux exigences des clients du monde entier.

Si vous pensez à l’usinage par électroérosion, ONA est probablement le meilleur choix.

98%

Taux de rendement global (TRG)

60

de pays dans les 5 continents dotés des machines ONA

15.000

machines installées partout dans le monde

70

différentes configurations de grandes machines

ÉTUDES DE CAS

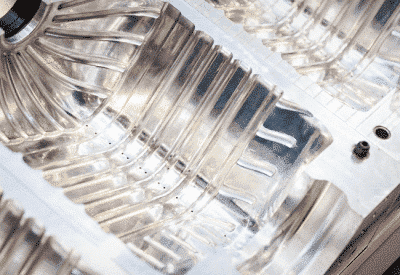

Les avantages de l’électroérosion pour le secteur de l’automobile

Les avantages de l’électroérosion pour le secteur de l'automobile : Le pari du principal fabricant de véhicules électriques pour ONA.

ONA met en œuvre des machines d’électroérosion Volkswagen Autoeuropa

Volkswagen Autoeuropa acquiert deux machines d’électroérosion ONA: ONA AV35 et ONA QX4 pour son espace presse et l’estampage de pièces.

L’EDM pour fabriquer des matrices d’ébavurage à PSA Peugeot Citroën

PSA Peugeot Citroën à Mulhouse possède neuf machines d’électroérosion d’ONA pour la fabrication de matrices d’ébavurage.

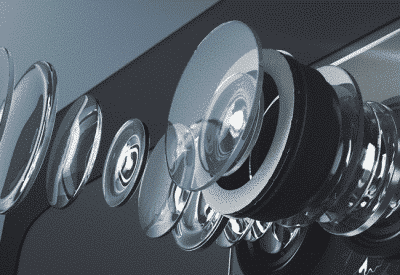

Machine d’électroérosion personnalisée de découpe d’anneaux de turbines

Solution sur mesure : Flexibilité et personnalisation d’une machine d’électroérosion par fil pour couper des anneaux de turbines de gaz.

NOUVELLES

Les avantages de l’électroérosion pour le secteur de l’automobile

Les avantages de l’électroérosion pour le secteur de l'automobile : Le pari du principal fabricant de véhicules électriques pour ONA.

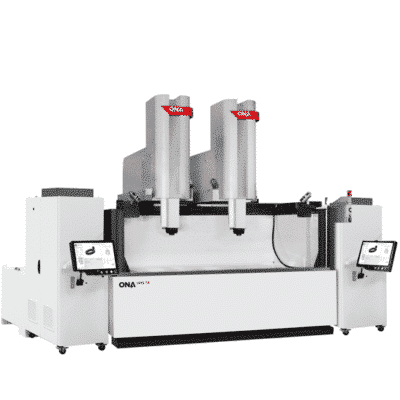

NOUVELLE ONA IRIS: la révolution en électroérosion par enfonçage

EDM par enfonçage ONA IRIS : Outils numériques, puissant moteur graphique et générateur 100 % numérique, configurable et programmable.

\ NOUVELLES

Les avantages de l’électroérosion pour le secteur de l’automobile

Les avantages de l’électroérosion pour le secteur de l'automobile : Le pari du principal fabricant de véhicules électriques pour ONA.

NOUVELLE ONA IRIS: la révolution en électroérosion par enfonçage

EDM par enfonçage ONA IRIS : Outils numériques, puissant moteur graphique et générateur 100 % numérique, configurable et programmable.