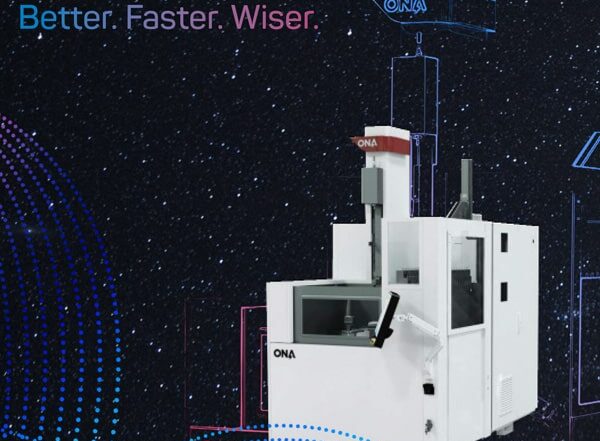

Possibly the world’s

best EDM choice

The ONA experience is the best choice you can make: the team of people with the most expertise in EDM together with a technological approach aimed at offering customised technical solutions where the focus is always on the particular needs of each customer and in their future profitability.

And all of this comes with the guarantee of quality and reliability offered by a brand that is a pioneer in EDM with more than 60 years of experience in developing technical solutions adapted to the requirements of customers around the world.

If you are considering EDM, ONA is probably the best choice.

What do you

need to create today?

Discover all our Electrical Discharge Machining services

Complete customised

EDM solutions

We offer integral customised solutions for the manufacture of pieces using EDM technology or a combination of processes. We do research and develop the best option for software, electrodes, program generation, technology, special machines… and we are closely involved in the process start-up.

We work with the client and analyse their needs in order to design customised machines. Each project is unique which is why we develop exclusive manufacturing processes for each one and optimise their productivity with more accurate results in their pieces.

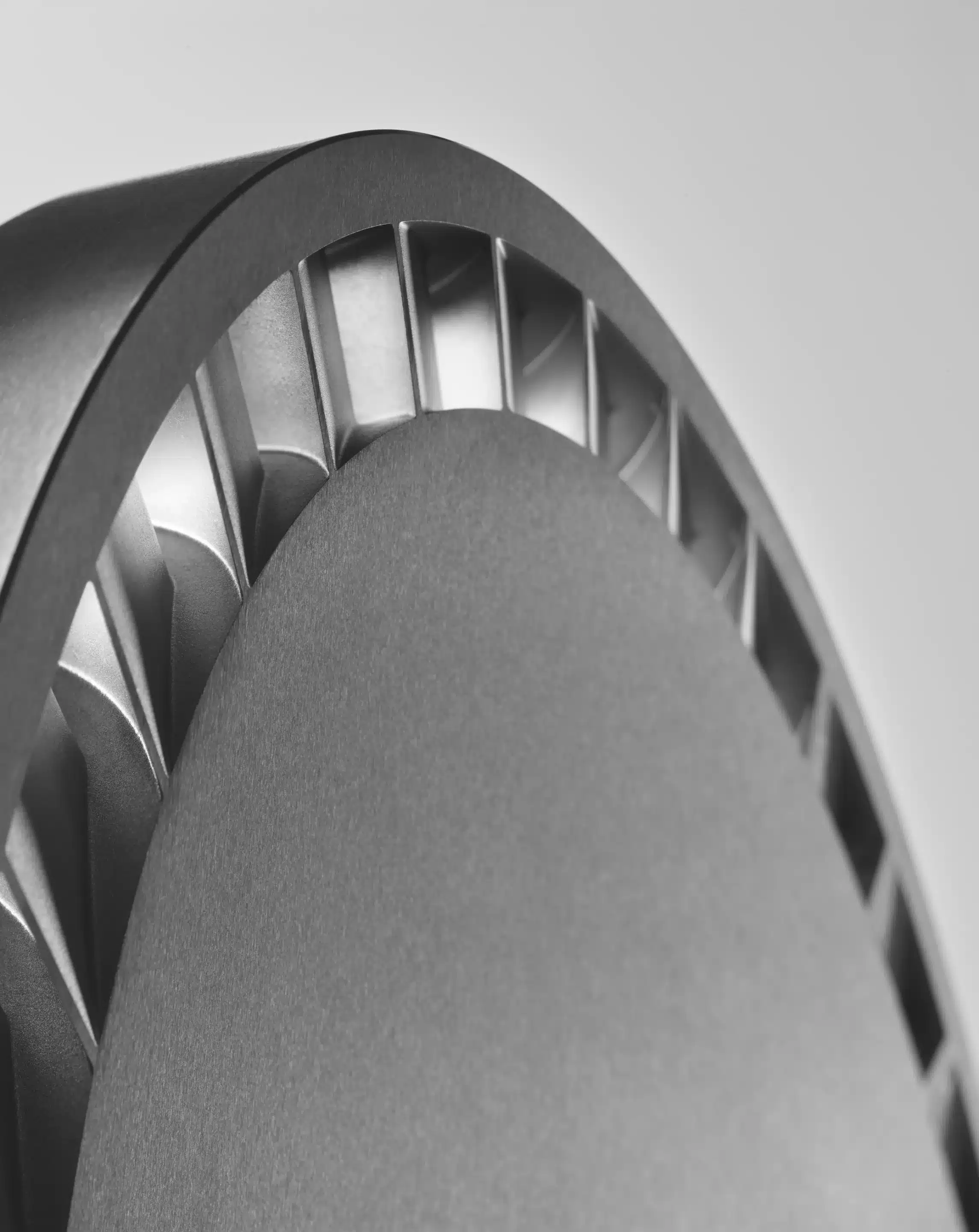

TURBOMACHINERY

In the Turbomachinery sector, EDM allows high-precision machining of complex geometries in tough materials like superalloys, reduces tool wear, minimizes thermal stress, and is versatile for both prototyping and mass production.

AUTOMOTION

In the automotive sector, EDM is essential for producing high-precision parts like engine components, gears, and molds. It enables the machining of hard materials with complex geometries while ensuring high durability and accuracy, which is critical for the efficiency and performance of vehicles.

MICROELECTRONICS

In the microelectronics sector, EDM is essential for its high precision in machining intricate components like microchips and circuits, particularly in hard-to-machine materials. It enables detailed cuts with minimal thermal damage, ensuring the integrity of delicate parts while supporting both prototyping and mass production.

MOULDING

In the moulding sector, EDM is crucial for producing highly precise and intricate mold cavities in hard materials. It enables detailed features and complex designs, ensuring high-quality surface finishes and accuracy, while also being effective for both custom prototyping and large-scale mold production.

TURBOMACHINERY

In the Turbomachinery sector, EDM allows high-precision machining of complex geometries in tough materials like superalloys, reduces tool wear, minimizes thermal stress, and is versatile for both prototyping and mass production.

AUTOMOTION

In the automotive sector, EDM is essential for producing high-precision parts like engine components, gears, and molds. It enables the machining of hard materials with complex geometries while ensuring high durability and accuracy, which is critical for the efficiency and performance of vehicles.

MICROELECTRONICS

In the microelectronics sector, EDM is essential for its high precision in machining intricate components like microchips and circuits, particularly in hard-to-machine materials. It enables detailed cuts with minimal thermal damage, ensuring the integrity of delicate parts while supporting both prototyping and mass production.

MOULDING

In the moulding sector, EDM is crucial for producing highly precise and intricate mold cavities in hard materials. It enables detailed features and complex designs, ensuring high-quality surface finishes and accuracy, while also being effective for both custom prototyping and large-scale mold production.

ONA IRIS-08B1L+ with 200-amp generator boosts productivity at Schlumberger

Schlumberger boosts its productivity with the new ONA IRIS-08B1L+ equipped with a 200 amp generator

EDM for the machining of the largest turbine disc firtrees.

ONA’s WEDM technology has proven to be a match for conventional methods such as broaching and milling in terms of quality and precision

Dubral optimises the precision and quality of its cutting with ONA AV35 model

The acquisition of the ONA AV35 model has allowed the company to improve the precision in its cutting, increasing efficiency

Sermec acquires the ONA AV35 machine to strengthen its EDM machining capacity

This fleet currently includes 4 wire EDM machines (AF25, AF35, AV25 and AV35), as well as a DR2 model erosion drilling machine.

ONA EDM technology optimises the performance of the MCM production process

The acquisition of ONA’s AV25, AV35 and AV60 models has meant an increase in profitability and quality for MCM and a high level of satisfaction.

Sabacaucho to machine large moulds for elastomeric parts with the ONA IRIS8 B1L+ machine

Sabacaucho’s requirement for a machine with a high capacity for machining and repairing larger moulds led the company to contact ONA.