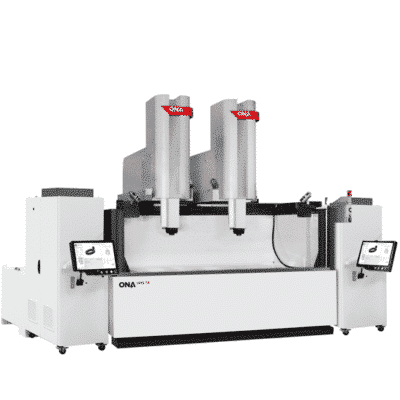

\ Possibly the world’s best EDM choice

The ONA experience is the best choice you can make: the team of people with the most expertise in EDM together with a technological approach aimed at offering customised technical solutions where the focus is always on the particular needs of each customer and in their future profitability.

And all of this comes with the guarantee of quality and reliability offered by a brand that is a pioneer in EDM with more than 60 years of experience in developing technical solutions adapted to the requirements of customers around the world.

If you are considering EDM, ONA is probably the best choice.

98%

Overall equipment effectiveness (OEE)

60

More than 60 countries with ONA machines

15.000

More than 15.000 machines installed all over the world

70

More than 70 large machine configurations

CASE STUDIES

AarKel achieves new levels of excellence in EDM machining with ONA.

AarKel has succeeded in standing out in EDM machining thanks to the collaboration with ONA with the installation of ONA QX8 and ONA IRIS T10 C2 models.

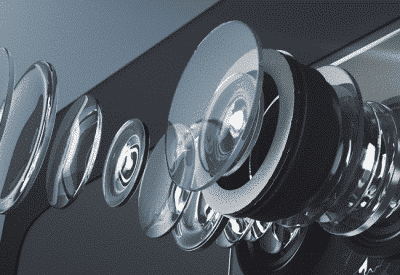

ONA Fast Hole Technology: the cutting-edge solution for more efficient turbines

ONA revolutionises hole drilling in the aeronautical sector with its Fast Hole technology. This technology allows complex holes to be produced in any conductive material with perfect finishes

MF5 Micro-hole EDM machine: Precision and cost reduction

Dynomite Diesel Products Inc. managed to reduce its costs thanks to the MF5’s micro-hole EDM machine in the manufacturing process of injectors

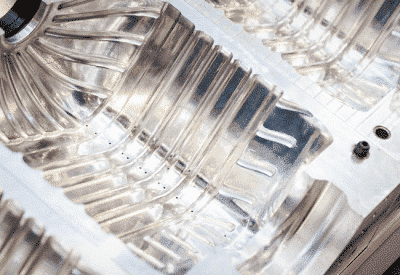

Alcapur Soperfect trusts in ONA for the production of complex parts

Alcapur – Soperfect places its trust in ONA as an EDM solution for the manufacture of complex parts that require high accuracy.

NEWS

ONA EDM makes strides in decarbonization.

The MTPRINT project aims to develop a specific Corporate Carbon Footprint calculation tool for the sector.

Interview Joan Pages, Commercial representative for Catalonia, the Centre and the East

Interview Joan Pages, "the future of EDM is to investigate improvements to increase performance and speeds"

\ NEWS

ONA EDM makes strides in decarbonization.

The MTPRINT project aims to develop a specific Corporate Carbon Footprint calculation tool for the sector.

Interview Joan Pages, Commercial representative for Catalonia, the Centre and the East

Interview Joan Pages, "the future of EDM is to investigate improvements to increase performance and speeds"