\ Wohl die beste EDM-Option der Welt

Die Erfahrung mit ONA ist die beste Wahl, die Sie treffen können: Ein aus Menschen mit der höchsten Kompetenz in EDM bestehendes Team in Kombination mit einem technologischen Ansatz, der darauf abzielt, individuelle technische Lösungen anzubieten, bei denen sich der Fokus stets auf die speziellen Bedürfnisse jedes Kunden und die zukünftige Rentabilität für ihn richtet.

All dies geht mit der Garantie für Qualität und Zuverlässigkeit einher, angeboten von einer Marke, die Vorreiter im EDM-Bereich ist und über 70 Jahre Erfahrung in der Entwicklung von technischen Lösungen aufweist, die sich an die Anforderungen der Kunden weltweit anpassen.

Wenn Sie EDM-Lösungen benötigen, ist ONA wohl die beste Wahl.

98%

Gesamtanlageneffizienz (OEE)

Mehr als 60

länder mit ONA-Maschinen

Mehr als 15.000

maschinen, die auf der ganzen Welt installiert sind

Mehr als 70

große Maschinenkonfigurationen

FALLSTUDIE

PVS Moldes bestätigt Die Vorteile der 3D-Metalldruck-Lasertechnologie von ONA

PVS MOLDES setzt auf ONA, um die Vorteile der 3D-Metalldruck-Lasertechnologie in seinen Fertigungsprozess zu integrieren.

Additive Fertigung von Metallen für die Hightech-Industrie

Hochschulen setzen auf Addilan, um stark technologisch ausgerichteten Industriezweigen Systeme für die additive Metallfertigung zu bieten.

Kundenspezifische EDM-Lösung mit geringeren Kosten

ONA bietet der Firma WUXI TURBINE BLADE eine maßgeschneiderte EDM-Lösung: Geringere Kosten verglichen mit anderen Angeboten auf dem Markt.

Hohe Präzision und Produktivität der EDM-Maschinen von ONA

Die Grupo Windsor Tooling-Plasman setzt aufgrund der hohen Präzision und Produktivität der Erodiermaschinen auf ONA.

NACHRICHT

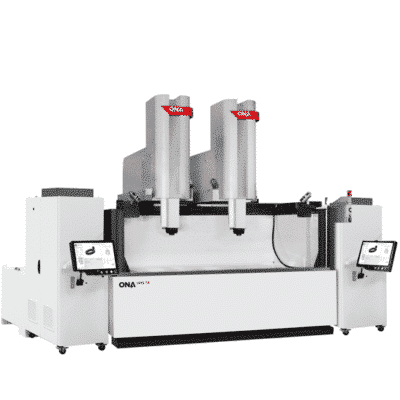

Kundenspezifische und hochwertige Maschinen für den Luftfahrtbereich

Unsere Strategie besteht darin, Luftfahrtunternehmen maßgeschneiderte Erodiermaschinen mit hohem Mehrwert zu bieten.

Script Programming: Intelligente adaptive EDM-Bearbeitung.

Script Programming: Intelligente EDM-Bearbeitung mit dynamischen Programmen zur Verbesserung von Herstellungsverfahren.

\ NACHRICHT

Kundenspezifische und hochwertige Maschinen für den Luftfahrtbereich

Unsere Strategie besteht darin, Luftfahrtunternehmen maßgeschneiderte Erodiermaschinen mit hohem Mehrwert zu bieten.

Script Programming: Intelligente adaptive EDM-Bearbeitung.

Script Programming: Intelligente EDM-Bearbeitung mit dynamischen Programmen zur Verbesserung von Herstellungsverfahren.